The bag is a simple sheath made from appropriate

cloth, such

as canvas or rip-stop nylon. A cloth handle is sewn at the point where

the case balances with the horn inside. An optional shoulder strap

extends

from one end to the other, and allows the case to be carried either

over

the shoulder or behind the back (semi-backpack style). The Author's

sheath

was made by Donna Altieri of Altieri Brass Pacs, 1 Galapago Street,

Denver CO 80223, phone 303-291-0658 (the tube was sent to her by UPS

for

fitting.)

www.altieribags.com

To give the bag shape and protect the instrument from

banging into obstructions

(and to resist crushing), the bag is sized to slip over a tube rolled

from

1/8" thick high density polyethylene plastic sheet. This is inexpensive

and may be obtained from local plastic supply companies or online from

suppliers such as GE Polymershapes (formerly Cadillac Plastics).

www.gepolymershapes.com

(www.cadillacplastic.com)

The diameter of the tube is made to be slightly less than

the overall

diameter of the bell. The length of the tube is about one inch more

than

the overall length of the instrument, to accomodate the bow pad

assembly

(see below).

|

|

To roll the tube, cut the sheet to size, allowing

about 3"

of overlap as shown in the photo. Use two or three cloth belts with

continuous-

adjust type buckles; the inexpensive belts used by the scouting

organizations

or the military for their unforms work well. Otherwise, any strap or

rope

method that allows the tube to start wide and loose, then be slowly

drawn

up smaller and tighter will work.

Once the tube is drawn up to the correct diameter (double

check this!),

drill appropriate holes in two rows, approximately 3/8" from each edge

of the plastic. The holes should be just large enough to clear the

pop-rivets

or other hardware.

Using two people, one reaching inside and other other

working outside

the tube, secure the hardware in the holes (NOTE: you must use

hardware,

since there is no glue or adhesive that will work with polyethylene

plastic.)

The photo shows aluminum pop-rivets (inserted from the outside, with

washers

used on the inside), but simple bolts, washers and locknuts will also

work.

|

|

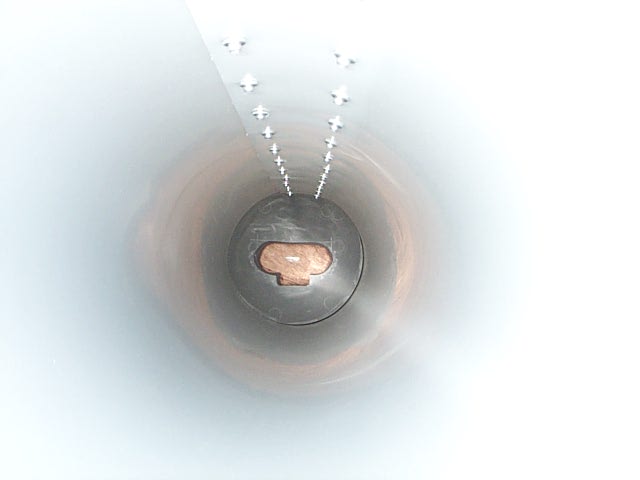

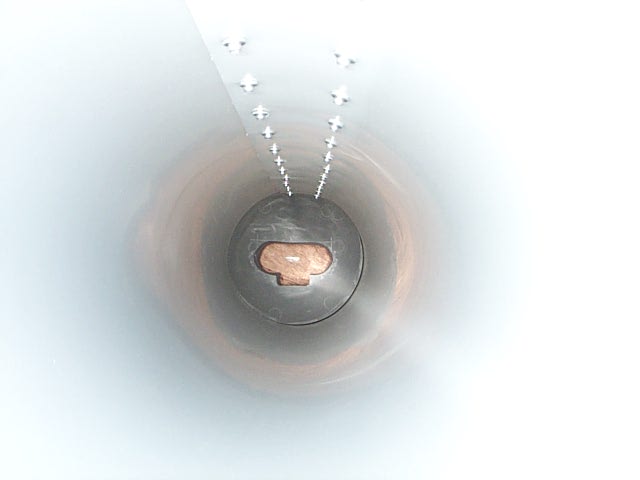

This photo shows the inside of the tube with all but

one of

the fasteners installed. The washers are clearly visible. Whether using

bolts or rivets, select them to be as short as possible to avoid

leaving

objects that will catch on the instrument when taking it in and out of

the tube.

|

|

The bottom bow of the instrument will be held in a

centered

position in the bottom of the tube. To provide a firm base for the bow

to rest on, and to provide a glue-friendly surface to attach foam

padding

to, cut a circle of plywood to fit inside the tube. 90-degree metal

brackets

are used with rivets and/or bolts to secure the wood just inside the

end

of the tube. The wood should be no more than 1/4" thickness to save

weight.

|

|

A pad made from a firm grade of foam is cut to fit

snugly inside

the tube, then cut to fit the contours of the bottom bow of the

instrument;

make allowances for any keys down there! There are a great number of

suitable

foam products which will hold the bow in place on the board; use at

least

a 2" thickness, and select a foam that is stiff enough to keep the bow

from slipping out of its cutout. A resilient foam formulation is also

desirable,

so that it recovers from abuse and will not crumble or tear. Plastics

suppliers

or foam cutting firms can often supply scraps of suitable material. The

prototype used 2-pound closed-cell crosslinked polyethylene in

a

2" thickness. Use RTV silicon adhesive (NOT caulk) or 'liquid

nails'

type adhesive to glue the foam to the plywood.

|

|

This photo shows the tube inserted into the bag, with

the instrument

inside. Notice how the bell self-centers in the tube. If the tube is

the

correct length, the bottom bow of the instrument will be just touching

the plywood board when the bell rests lightly on the rim of the tube.

The original design does not have any padding for the bell,

but this

can be added by sewing foam rubber to the cloth sheath just where it

touches

the bell rim. Another solution would be to make a short tube slightly

larger

in diameter than the main tube, sized to fit just around the bell, and

fasten it to the main tube, providing a lip that the bell would rest

inside.

|

|

This photo shows the correct cut of the cloth sheath.

With

the tube snugly inside the sheath, there should be just enough extra

cloth

to draw almost to the center of the bell with a drawstring. Provide a

slit

in the sheath starting about an inch below the top of the tube, to

allow

the end to be opened wide when taking the instrument in and out. The

drawstring

and slip fastener are available at fabric stores and suppliers of

camping

equipment. The tightly drawn string holds the bell firmly inside the

tube,

so the instrument cannot move sideways or lengthwise inside the tube.

|

|

This photo shows the completed gig bag with the

ophicleide

inside. If the optional outer ring is added to the bell end of the tube

(see above), the instrument will be very well protected from abuse in

transit.

Since most ophicleides are narrower than their detachable bocals (some

players refer to these as 'crooks'), it is not possible to size the

tube

to also fit the bocal inside. The bocal can be easily carried

separately

in whatever other bag or case the player might take along (the author

puts

it inside an attache case that primarily holds sheet music.)

The descriptions given here and the

photos

reflect a gig bag in use for almost 10 years, including about 20 trips

by airplane (the gig bag was placed inside a custom made cardboard box,

fabricated by the local packaging store.) However, no guarantee is made

for suitability for a given instrument or travel situation, or for

variations

on examples made from these descriptions.

All photos made using a Kodak DC240

digital

camera.

|

|