When gluing the four trapezoids to make the tube, they must be held

firmly together over the entire length, they must be kept straight without

a twist, and the whole assembly must stay in alignment. The individual

trapezoids will be quite floppy, and without help will bend every which

way.

To facilitate the gluing, two sets of 'jigs' must be made from left

over plywood. A set of thicker 'inner jigs' will prevent the trapezoids

from falling inwards; the rabbet joints will do the rest in this regard.

Another set of 'outer jigs' will keep the assembly aligned, and will also

help keep the pieces together while the glue sets.

|

|

The outer set consists of nine jigs, each made from a 6" x

6" piece of plywood. They will be located evenly along the length of the

tube, with the exception of the two on the ends, which must be slightly

inwards. Centered on the jigs are square cutouts, sized progressively to

match the outer dimensions of the tube at their respective locations.

Before sawing the inner cutouts, drill holes at the corners. This will

assist the sawing, but more importantly the clearance they afford will

prevent conflicts with the corners of the tube. Also, this clearance keeps

excess glue that squeezes from the rabbet joints from adhering to the jigs.

|

|

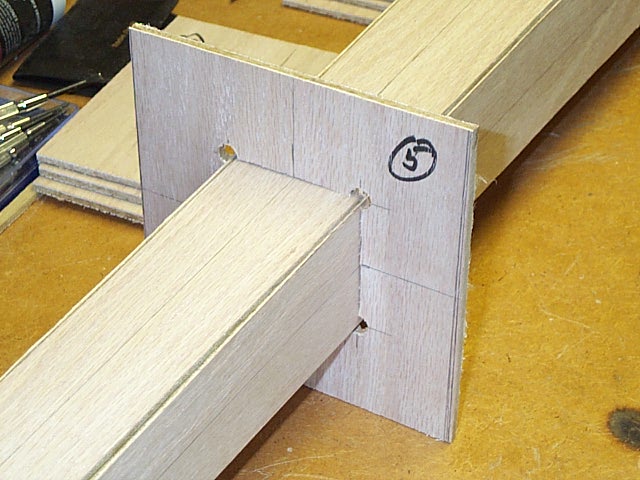

This photo shows the trapezoids being held together by the

outer jigs, as part of a test fitting prior to actual gluing. The utility

of the corner holes is clear from this view.

As long as the tube is glued together while the jigs rest on a flat

surface, the resulting structure will be straight and true.

This photo also shows how floppy the trapezoids can be. Note that while

the jig holds the pieces together at one point, the pieces start to separate

a few inches away. For this reason, tightly wrapped and twisted steel wire

will be used as the primary tightening method.

|

|

The inner set consists of four jigs, three of which are made

from thicker pieces of wood; the fourth will be a 1/2" dowel rod. Use 1/2"

or

3/4" plywood or other board if available. Otherwise, a few pieces of scrap

from the main plywood sheet can be glued together to make thicker pieces

for this purpose.

These jigs will be spaced evenly along the length of the tube. They

will need to be attached temporarily to one of the trapezoids. During fabrication

of the prototype, the inner jigs were stapled to the trapezoid.

Note that this photo shows a piece of plywood attached to the small

end of the trapezoid; ultimately this was replaced with a short section

of 1/2" dowel prior to gluing. The dowel was taped in place instead of

being stapled.

|

|

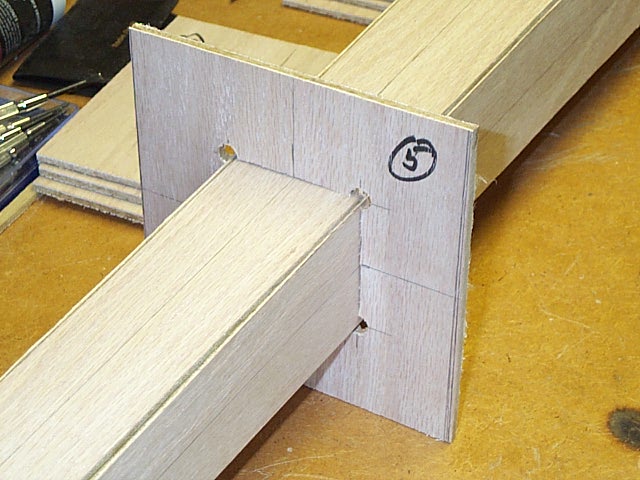

This photo shows one of the inner jigs in place, stapled to the trapezoid.

Note that only one trapezoid will be stapled to the inner jigs! Without

the staples, the inner jigs would shift and prevent proper alignment of

the pieces during the critical gluing process. Also, the jigs might possibly

fall over, ruining the whole thing.

As with the outer jigs, the inner jigs need to have clearance at the

corners in order to avoid conflicts and inadvertent glue bonding to the

trapezoids. The corners of the jigs have been sanded to a rounded shape.

A hole must be drilled in each of the three square shaped jigs; the

photo shows the hole off-center, but experience dictates that a centered

hole will be better. A length of cord will be fed through the holes and

knotted, with some slack between each jig. After gluing, the inner jig

staples will be pulled out, and the inner jigs will be extracted from the

tube by tugging on the cord.

|

|

This photo shows the staple holding one of the inner jigs in

place. A pair of small nails would also work (one nail alone would allow

the jig to twist); make sure to use nails with flat heads, so that they

can be pulled easily..

After gluing, the staples will be pulled, and their holes filled by

rubbing wood glue into them.

Visible here is the asymmetrical shape of the trapezoid. The center

line, marked in pencil, defines the true center of the tube, but the wood

extends further to one side as part of the rabbet joint structure. When

positioning the inner jigs, make sure that they are aligned accurately

relative to the true center line. The previously mentioned test fitting

is important in verifying this alignment.

All photos made using a Kodak DC240 digital

camera.

Go to next chapter

|

|