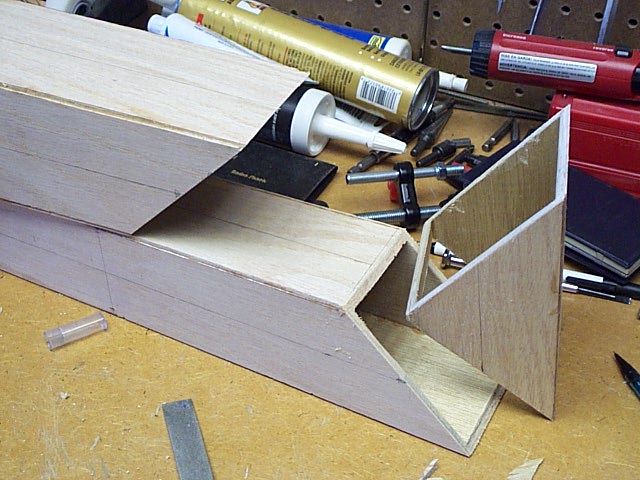

In order to reshape the instrument to a form convenient for playing,

some 'bends' will need to be made in the tube. The Squarpent uses a shape

similar to a baritone saxophone, requiring only five cuts to make the bends.

Refer to the downloadable documents for detailed information on where

to make the cuts.

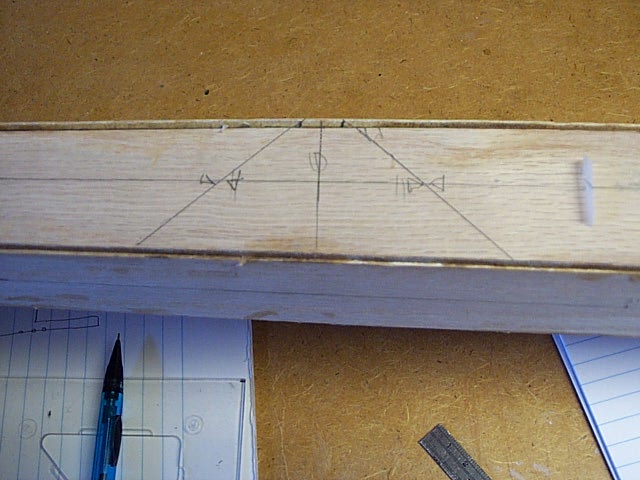

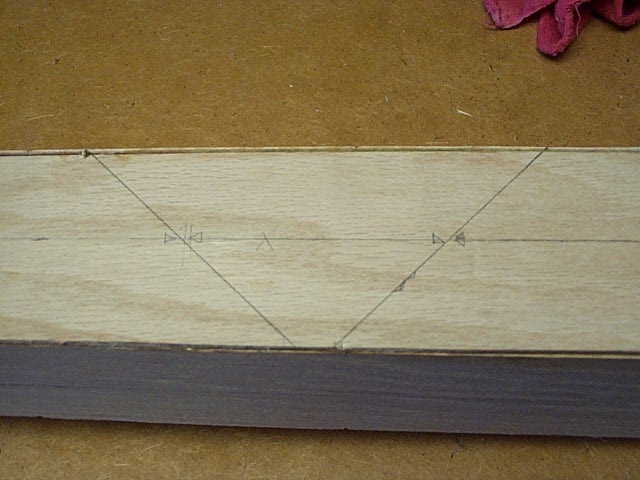

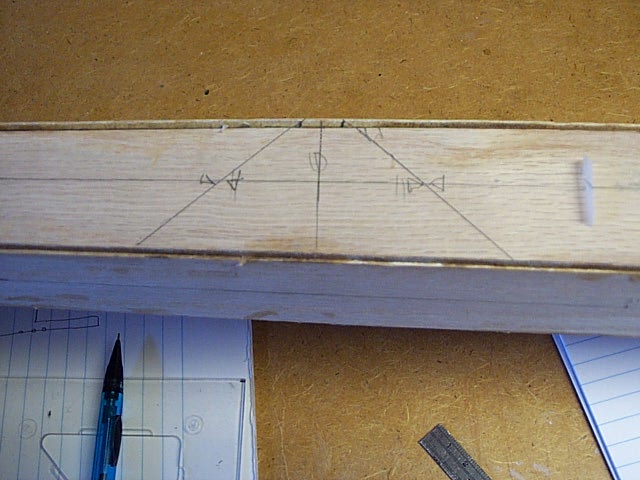

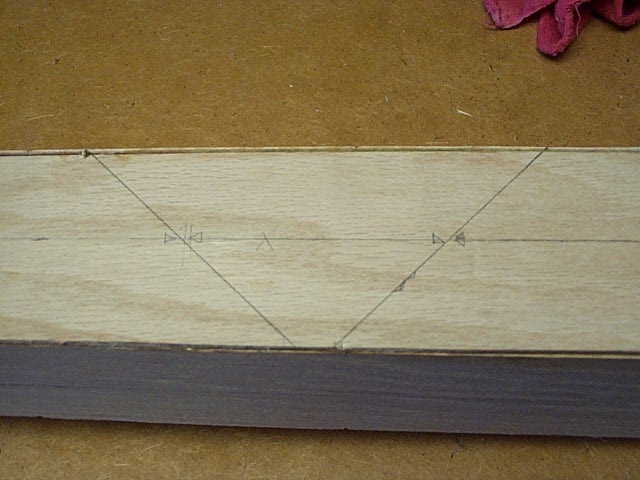

Measuring along the bore centerline from the mouthpiece end of the tube,

mark the five cut locations. Then, using an accurate angle or square, draw

guide lines as shown in the photos. On the plane of each cut, the line

will be at 45 degrees relative to the centerline (NOT relative to the side

of the tube!)

Not shown in the photo are the extensions of the cut lines. Once the

saw has been started on the diagonal cut line, it will be useful to have

guide lines on the two adjacent sides of the tube to help keep the saw

straight. These lines will be at 90 degrees to the centerlines, and will

match the ends of the first (diagonal) cut line. The fourth side of the

tube will not need a line.

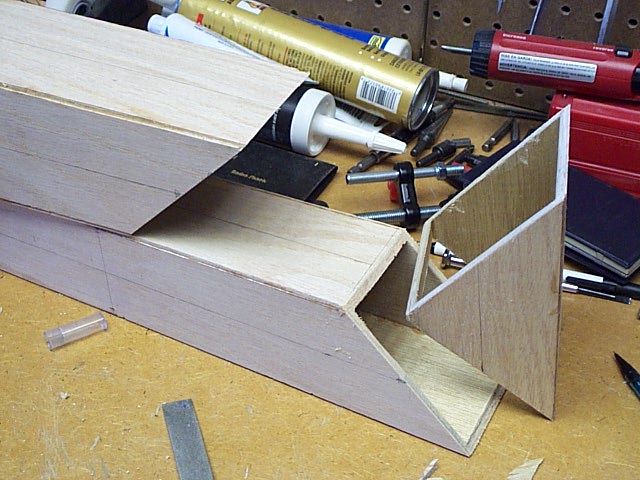

This photo shows the first cut (Cut A) nearest to the small, or mouthpiece,

end of the tube.